By Georgie Holgate-Stuckey

In 2026, the global LED display market is forecast to surpass $19 billion. Stadiums, digital-out-of-home (DOOH) networks, transit hubs, and public realm projects are all embracing LED technology to drive engagement, revenue, and public information. But while demand is surging, so is the number of high-profile failures.

From dead pixels on newly installed 4K displays to power issues in extreme weather conditions, the risks of getting LED procurement wrong are real. And costly.

As digital infrastructure becomes more central to how we experience live events, navigate urban spaces, and consume branded content, decision-makers are waking up to a crucial truth: LED screens aren’t commodities. They are engineered assets.

Beyond the Box: What You’re Really Buying

It’s tempting to treat LED screens as plug-and-play products. Many vendors encourage this mindset, offering standard cabinets, flashy spec sheets, and rock-bottom pricing. But in complex environments, that thinking breaks down.

A concourse LED ribbon in a 60,000-seat stadium is not the same as a shopfront ticker. A roadside DOOH billboard faces different wind loads, ambient light, and structural demands than an indoor totem in a shopping centre.

Procurement teams focused only on cost per square metre are missing the bigger picture: performance, longevity, and total cost of ownership.

According to Grand View Research, failure rates on LED modules can range from 3% to 20% annually depending on the environment and quality. That means a 4K screen could have hundreds of faulty pixels within the first year if quality control isn’t rigorous.

The High Cost of Getting It Wrong

When LED infrastructure fails, the damage goes far beyond technical issues. It’s brand damage. Lost ad revenue. Contract disputes. Delays to venue openings. Reputation hits that spiral beyond the site itself.

Take the example of a well-known UK stadium that rushed through an LED installation in 2022. The result? Inconsistent brightness, visible dead pixels on match days, and an expensive retrofit just 18 months later. The short-term savings were erased by double the cost and months of disruption.

As James Dyson once said: “Designing and engineering is about understanding how things work in the real world, not just on paper.” That applies as much to LED screens as it does to vacuum cleaners.

What Great Procurement Actually Looks Like

Smart LED procurement starts upstream. It begins with understanding your site’s conditions, usage demands, access restrictions, and lifespan expectations. It’s about selecting a partner, not a product.

Look for vendors who offer structural engineering, not just screen sales. Who ask about mounting conditions, viewing distances, and brightness needs. Who can show you how their screens perform in rain, heat, and wind. Who talk about QC processes, repair timelines, and spares availability, not just pixel pitch.

And critically, who operate locally. Too many imported systems come with no UK servicing, no parts, and long waits when issues arise.

Build for the Environment, Not the Spreadsheet

In environments like stadiums, airports, and roadside billboards, every detail matters. LED hardware must be designed to fit not just the space but the context. Wind load. Access restrictions. Glare management. Structural weight limits. These factors don’t show up on spec sheets but can derail entire projects.

Real-world performance isn’t just about brightness and colour. It’s about thermal management, cabinet longevity, and electrical stability. It’s about integration with live data, wayfinding systems, or CMS platforms. That’s the difference between a screen that works and a screen that performs.

What’s Changing in 2026

Two forces are shaping LED investment decisions this year:

Higher commercial expectations

Whether it’s DOOH media owners seeking better CPMs or stadiums trying to monetise fan zones, LED is expected to deliver measurable ROI.

Sustainability standards

Environmental scrutiny is increasing. Clients are asking about product lifespan, recyclability, and energy usage. Smart procurement includes sustainability now.

These pressures demand a more mature, engineering-led approach to digital display investment. The conversation has shifted from “how many pixels?” to “how will this perform over time, in this environment, under pressure?”

How Merson Digital Helps

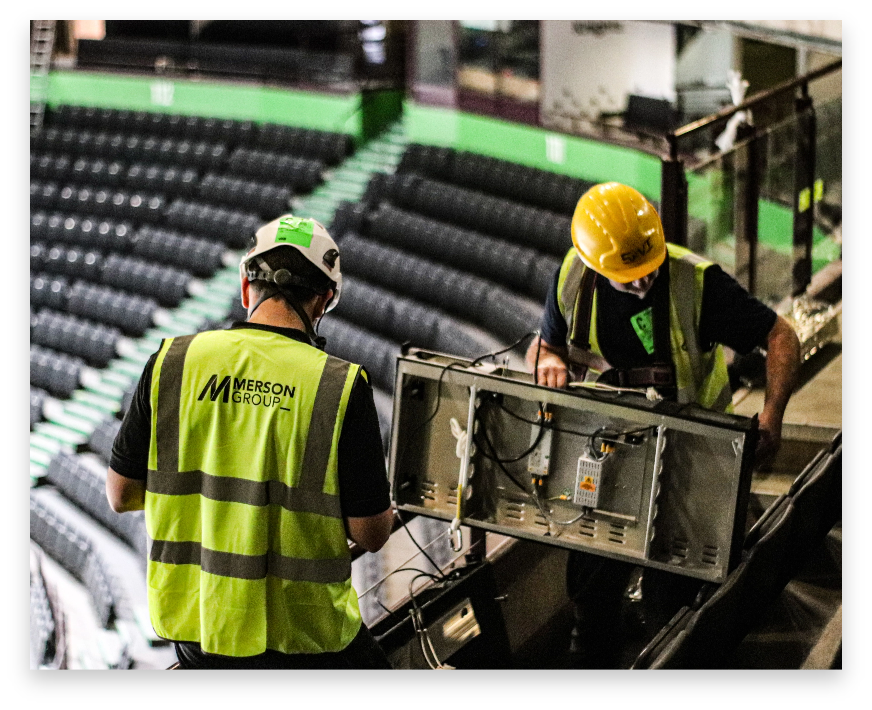

At Merson Digital, we engineer LED infrastructure that performs in the real world. We collaborate with architects, main contractors, and end clients from day one to design systems that last, structurally, technically, and commercially.

Our full-service delivery includes UK-based manufacture, M&E design, certified installation, and ongoing support. All backed by our partnership with YAHAM, one of the world’s most respected LED manufacturers.

If you’re planning a large-scale LED deployment in 2026, start with performance, not price.

Talk to us about building it right from the ground up!